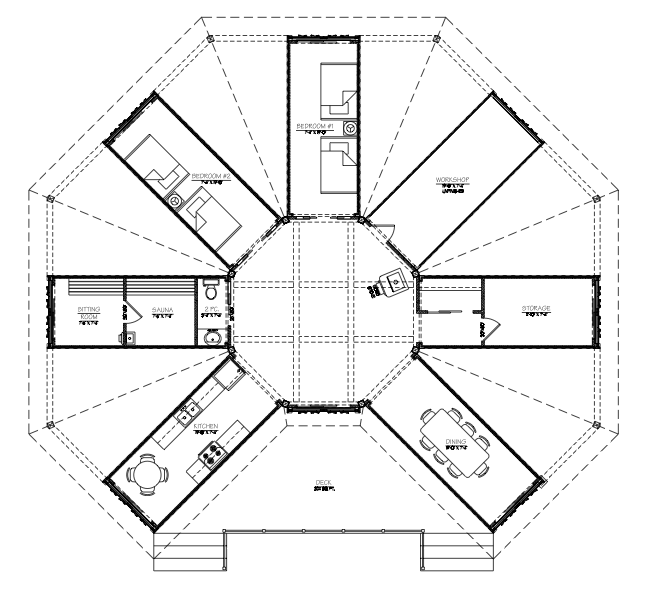

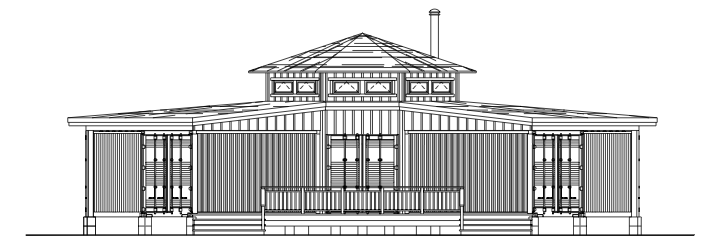

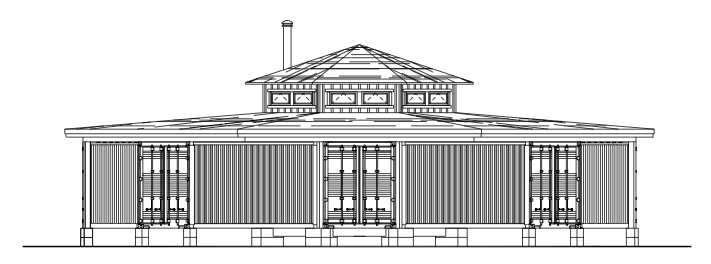

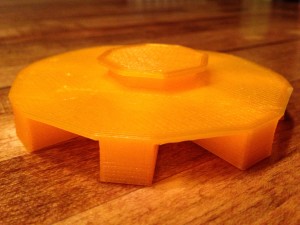

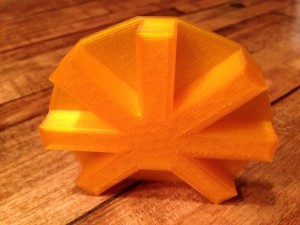

One of our excited project followers has taken the initiative of printing a scale model of our Shipping Container Cabin on his home built 3D plastic printer. For those of you who are unfamiliar with 3D plastic printing, there is a niche following of techies that design and build 3D printers that literally print out 3 dimensional objects using melted plastic droplets. Think of it as a miniature hot glue gun with brains, motorized controls, and a computer interface. This 3D model was printed using our original concept design for our shipping container cabin in Google SketchUp. As you can see, the end result looks just like our Project OCTOPOD!

We love it when people take the initiative to build creative projects with creative tools. Imagine the day when we can print out full scale housing?

In contrast to the previous post about using insulating coatings for ambient and cold temperatures, I would like to share my direct research on the use of ceramic coatings for high temperature applications.

In contrast to the previous post about using insulating coatings for ambient and cold temperatures, I would like to share my direct research on the use of ceramic coatings for high temperature applications.