This past winter was the coldest Ontario has seen in 20 years. Spring is officially here however the nicer weather hasn’t exactly arrived yet. After checking in with our builder, it appears we’ll need a little more patience before the roads dry up allowing us to get back into the construction scene.

During our planned sea container construction downtime, we have been busy preparing for our next steps.

1. Source big timbers

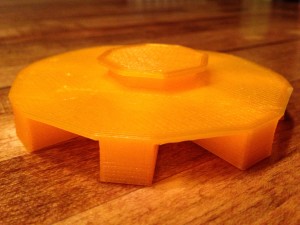

We believe in local sourcing to support the community and to reduce shipping costs. These savings will ultimately reflect in our final construction costs so we searched for a nearby sawmill with the capacity and capability to mill up dimensional timbers as large as 10″ x 10″, and some as long as 26 ft. Sure enough, just one concession road over from the project site, our friendly local sawmill was up for the task. Timbers of this size require a long lead time. Our order was placed months ago in order to align with our spring construction period.

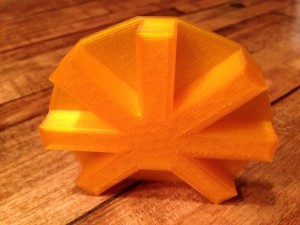

2. Source heavy steel brackets

Another long lead time item are the custom heavy steel brackets for connecting the post and beam timber works. For ease of on site assembly, and for the beefy rustic look, we decided to go with heavy steel brackets instead of custom fit hand carved joints. Once the final dimensions of the rough sawn timbers were confirmed, design and engineering of the brackets were finalized, and off they went into the fabrication shop for manufacturing, and over to the finishing shop for a hot dipped galvanized treatment.

Now we wait for the ground to dry up.

Once we mobilize the crane, the containers will be placed on their foundations. Then we start building the great room.

The following preparation and progress has occurred while the site lay in winter hibernation:

- Post and beam timbers sourced and cut, ready for delivery

- Manufacturing of enormous engineered brackets and hot dip galvanizing, ready for delivery

- Researching off-grid power and determining requirements of the cabin, keeping us busy – interesting findings on the latest energy storage technologies post to follow

- Documenting interior design requirements so that a furniture, electrical and lighting plan could be created to optimize the living space. We have an exciting interior designer engaged – deserving of her own dedicated post.

- Did we mention we’re hoping to have the sea container cabin project filmed for a TV series? Film producers are excited about the rich content of this project, so we’ll see if they can keep up with the speed of the build this summer.

First load of timbers for the great room are waiting to be delivered.

If you would like greater detail on any of these topics or just want to hear more about our experiences, contact us or leave us a comment below. Your interests do influence our future community blog topics. You can also follow us on our journey by signing up for our emails.